Auch verfügbar auf Deutsch

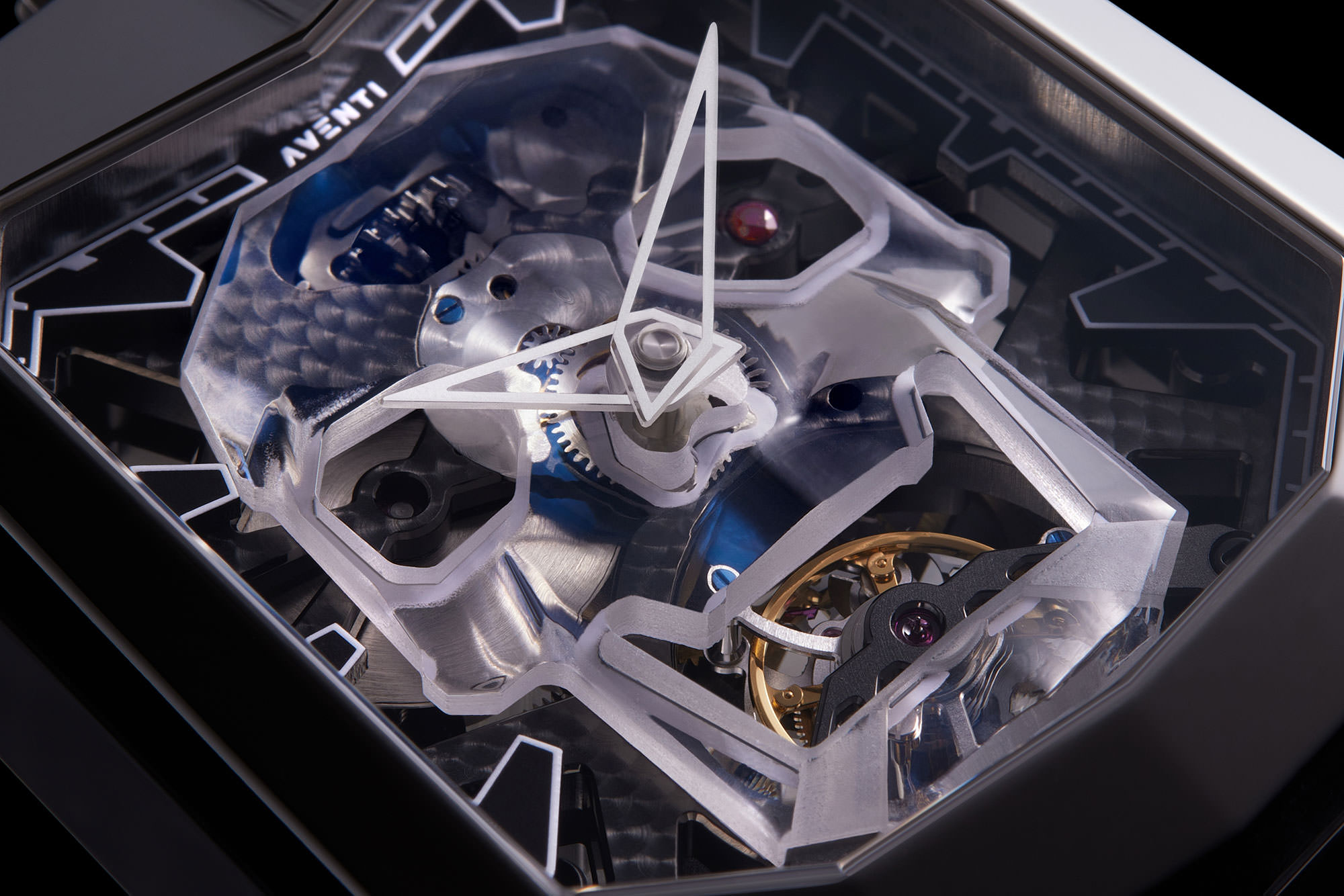

Introducing the Aventi A13-01 Ghost. The most complex single piece of sapphire in watchmaking – a sapphire skull with more edges and facets than a brilliant-cut diamond – is suspended over our first Swiss-made open work tourbillon: the GT-01S.

Available by allocation only – CHF 11,500.

500 hours of work to produce a single skull

Invisibly suspended over Aventi’s first Swiss-made openwork tourbillon is an industry-first, cementing Aventi as masters of Sapphire – the single piece Sapphire Skull. It takes over 500 hours to produce a single skull, and one mistake, smaller than a human hair, is enough to destroy everything. To put it in perspective, a brilliant-cut diamond has 58 individual facets. Our skull has 160 facets, 200 edges and is only 2.3mm thick.

The raw Sapphire is secured in the CNC machine with a custom retention system and intricately cut using diamond-tipped tools. Each piece of Sapphire must be re-set within the CNC 48 times to reach every facet. Every time the piece is reset, the CNC must be re-calibrated and measured in a process taking 5 hours with no room for error.

- 100% pure sapphire

- 160 facets 200 edges

- 2.3mm thick

- 7 layers of blue anti-reflective coating.

The swiss tourbillon, reimagined.

Aventi has created one of the highest quality movements, one that’s accurate, reliable and finished to an incredible level—focusing not only on the final result but also the most efficient, reliable and robust way to achieve it—a grand complication for everyday wear. We worked with master watchmaker Olivier Mory to develop a tourbillon that is more accurate than a chronometer, with over 4 days of power reserve. Shock resistant to over 5000 G’s and with magnetic resistance of 2000 gauss.

Something that can be worn for many generations to come.

63 components are mounted in the grade 5 titanium main plate compared to a traditional tourbillon with more than 300 possible points of failure. A traditional tourbillon cage is comprised of more than 40 individual components; ours is only 18. By minimising the number of components, we also minimised the number of potential risks.

Finished to a level in line with the best and guaranteed perfection through a quality control process like nothing our partners had seen before. Every edge bevelled and polished, every facet covered in intricate perlage, protected by a medical-grade black carbon coating. The final touch, a natural pigeon blood ruby, handset into the eye of the skull.

- +/-4 secs a day.

- Over 4 days of power reserve from a single barrel.

- 5000 g shock resistance, 2000 gauss magnetic resistant.

- Grade 5 titanium.

- All edges bevelled and polished, covered in perlage.

- Protected by a medical-grade carbon coating.

The rarest hands on any watch ever made.

Most hands are made from processed metals but rarely gems. Aventi has developed their sapphire hands to match the skull centrepiece’s complexity and brilliance. Every facet and edge is hand polished to perfection – with a thickness of 0.3mm. No traditional hand makers can produce these hands, only masters of Sapphire.

- Pure Sapphire crystal.

- 0.3mm thick.

- Bordered with BGW9 Super-LumiNova.

About Aventi

We have no offices. We have no boutiques. We have no workshops – we simply use the best talents and partners from around the world to coordinate an organisation taking on giants.

Our watches are made to a new global standard.

Aventi timepieces are not just purchased.

They are allocated based on strict criteria. These criteria are used to assign each piece to the best possible recipient and prevent profiteering and clients who don’t align with our family values. Aventi clients are those who have a real passion for watchmaking, those we consider true friends of the brand and respect our vision.

Media Contact: